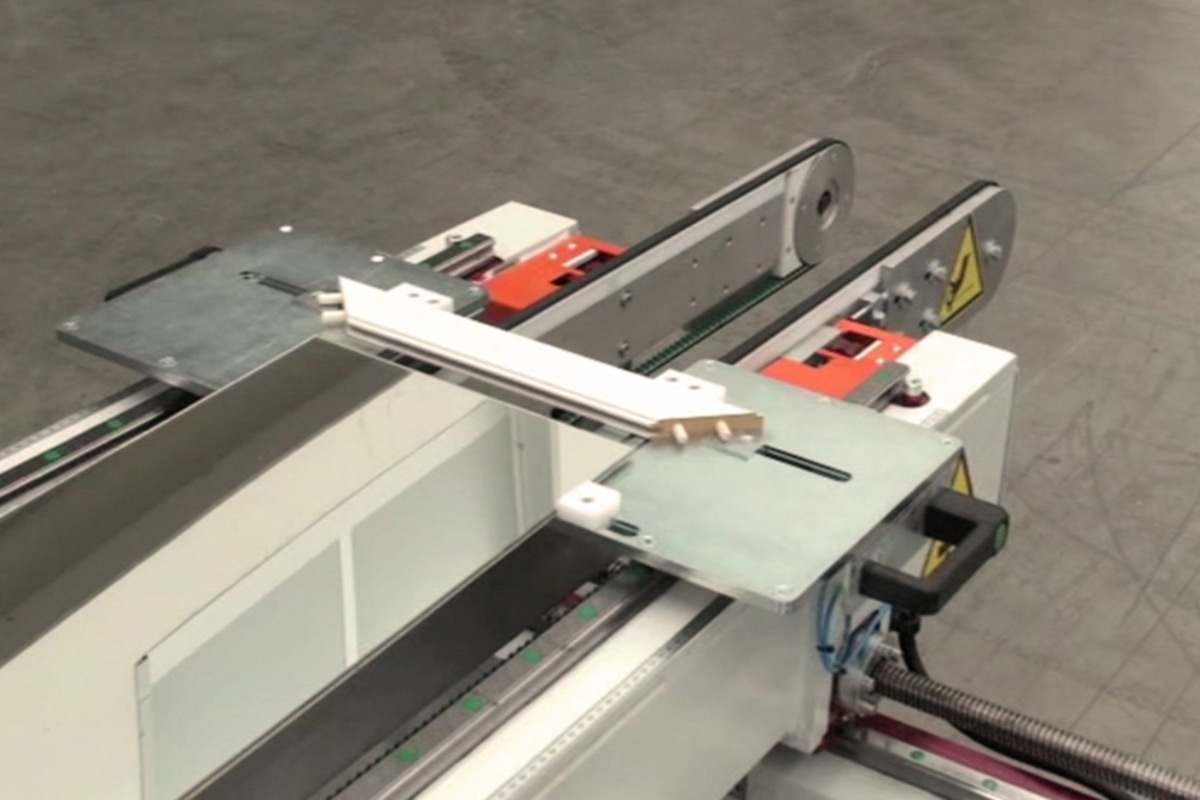

This machine is designed for assembling of inside doors and kitchen doors in wood or MDF, with 90° or 45° junction, and the possibility to have one or more panels both wood or glass.

The combination of vinilic and hot melt glue allow to have at the output of the machine a door perfectly fixed ready to be packed.

Every mechanical parts and relative dimensions change could be completely automatic.

Technical specifications

| Materials | MDF – Wood |

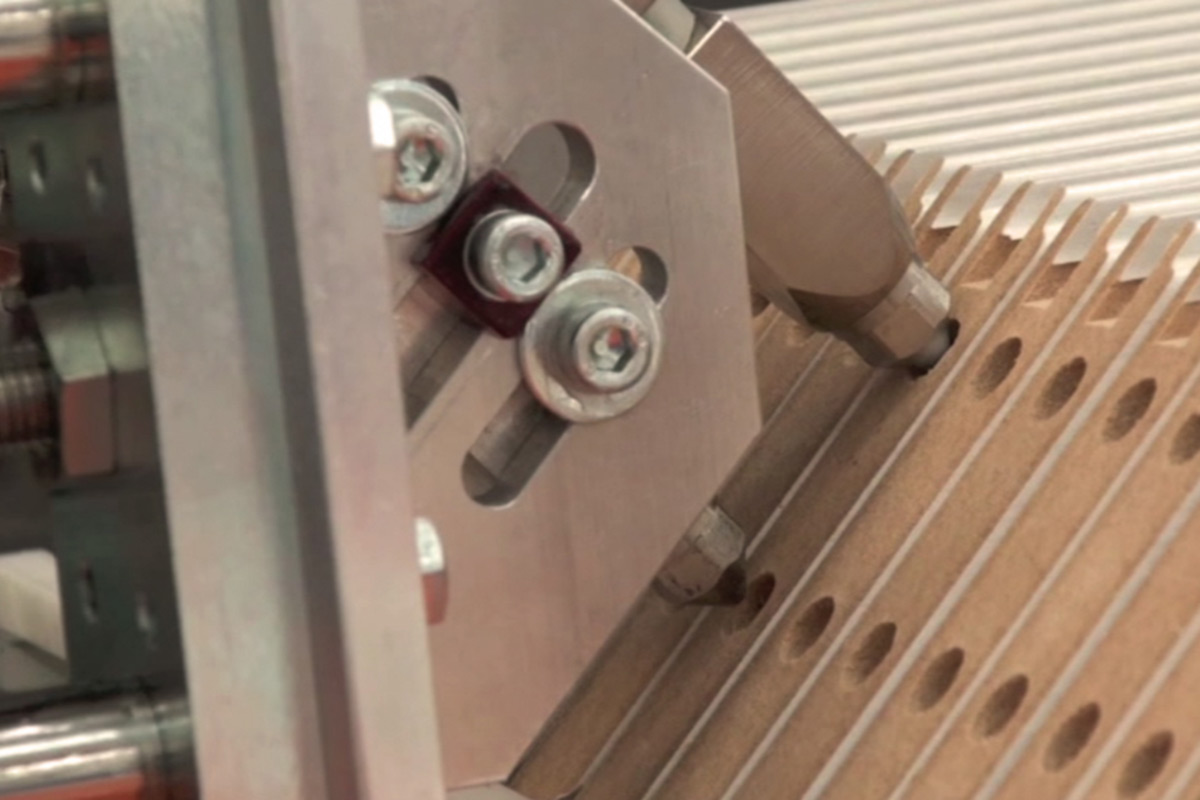

| Junction | 90°, 45° and cutting french |

| Speed | Up to 6 pcs/min |

Product dimensions

| Length | min 400 – max 2400 mm |

| Width | min 300 – max 800 mm |

| Thickness | min 18 – max 35 mm |

| Panels | Up to 5 |

Benefits

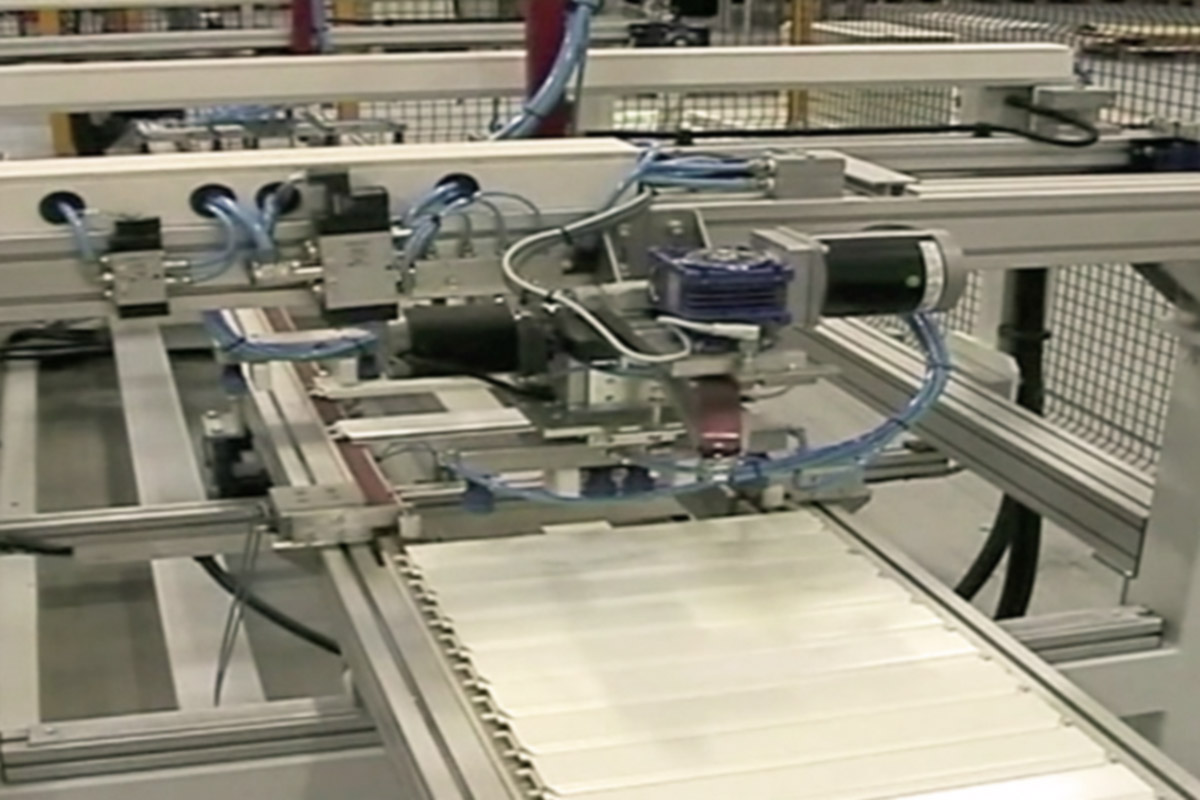

| Automatic honeycomb insertion inside the frame |

| Hot melt glue use as to have a hard and crushproof frame in the junctions |

| Perfect frame squaring and planarity |

| High efficiency due to no machine stop |

| No tools break because of staples during the working |